Our Project Profiles

The following Project Profiles are representative of the various projects we are engaged to provide our services.

The Arizona Biltmore Hotel - Phoenix, Arizona

Client Objectives

In the aftermath of a late-summer 2018 monsoon storm, ownership of the historic Arizona Biltmore Hotel engaged Arnold & Associates, Inc. (AAI) to:

✅ Conduct a comprehensive evaluation of storm-damaged roofing and all other roofs across the property.

✅ Provide immediate replacement of the wind-damaged East Wing roof.

✅ Develop a long-term, phased plan for roof replacement and repairs spanning several years.

✅ Complete all work while maintaining uninterrupted hotel operations.

Historic Significance

Opened in 1929 and designed by Albert Chase McArthur—a protégé of Frank Lloyd Wright—the Arizona Biltmore has long stood as an architectural icon. Over the decades, the resort has undergone multiple additions and renovations, most recently under the ownership of Blackstone Real Estate Investment Trust (BRE), which acquired the property in 2017.

The August 2018 monsoon storm damaged the East Wing roof, one of the original structures, triggering the involvement of the City of Phoenix Historic Preservation Department to ensure all repairs honored the property’s historic integrity.

Challenges & Deficient Conditions

AAI’s evaluation revealed several critical issues beyond storm damage:

✅ Roof Blow-Off: High winds stripped away significant portions of the East Wing’s roof membrane.

✅ Asbestos Contamination: Asbestos was found in multiple layers of roof membranes and on the original 1x wood decking.

✅ Excessive Roofing Layers: Up to nine prior roof systems had been installed over time without tear-offs, creating severe weight and stress on the structure.

✅ Structural Damage: Stressed framing members required reinforcement and replacement before a new deck could be installed.

AAI’s Solution

AAI led a comprehensive restoration effort that balanced historic preservation with modern construction practices:

✅ Developed complete construction documents, including detailed plans and specifications.

✅ Coordinated approvals with the City of Phoenix Historic Preservation Department.

✅ Partnered with structural engineers to address load-bearing deficiencies.

✅ Engaged asbestos abatement and environmental consultants for remediation.

✅ Oversaw roof replacement and framing restoration, ensuring compliance with safety and historic standards.

✅ Provided ongoing site observation on a 10-day rotation, verifying quality throughout the installation.

Following the East Wing roof replacement, AAI performed a full evaluation of all hotel roofs, cataloging deficiencies and establishing a prioritized plan for future roof replacements and waterproofing improvements.

Continuing Partnership

AAI remains actively involved with the Arizona Biltmore, providing expertise and project oversight for ongoing roof and waterproofing projects.

Owner: Blackstone Real Estate Investment Trust

Director of Engineering: Mr. Phil Hornstra – (602) 381-2593

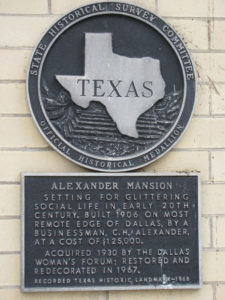

The Dallas Women’s Forum Alexander Mansion

The Dallas Women’s Forum

Alexander Mansion

4607 Ross Avenue

Dallas, Texas 75204

Client’s Objectives:

✅ Address life-safety aspects of the exterior façade and roofing of the historic facility originally constructed in 1906.

✅ Remove and replace deteriorated roofing materials and install a new modified bitumen roofing system.

✅ Design and complete repairs to address leaks in the roof areas and “worst-case” wall conditions.

✅Assess the repair and restoration requirements for exterior masonry and historic wood windows.

✅ Assess the removal and repair of unsafe structural issues.

✅ Assess historic detailing for columns, cast stone detailing, decorative metal, and windows.

|

|

|

|

Solution:

- The roof and facade of the historic Alexander Mansion had significant deterioration. The first task was to investigate the facility and identify recommended work, and classify that work as

- a life-safety requirement;

- roofing and waterproofing requirements to address interior leakage or significant deterioration; and other recommended exterior work associated with repair and waterproofing.

Due to funding issues, only “as-needed” and “urgent” issues were addressed during 2017. Additional work will be completed on the facility as funds and donations are acquired.

Texas Roof Management (TRM) and Frontier Waterproofing completed work on the building with design and recommendations by Arnold & Associates, Inc., in association with Holly Hall, Architect. Initial work was completed with the assistance of numerous pro bono donations, as well as materials and supplies provided by TRM and Siplast, Inc.

Hotel Monaco Denver

Preserving History, Enhancing Guest Experience

At Hotel Monaco Denver, a premier destination in downtown Denver, we successfully restored the historic windows of two iconic landmark buildings while keeping the hotel fully operational. Managed by Xenia Hotels & Resorts, Inc., this project balanced strict preservation standards with modern functionality, ensuring an exceptional guest experience.

Project Overview

The goal was to evaluate and restore the historic windows of two distinct buildings:

✅ Railway Exchange Building (1909/1913): A Beaux-Arts masterpiece with a Terra Cotta façade and large wood double-hung windows.

✅ New Building (1937): An Art Moderne gem featuring smooth limestone and expansive steel windows.

Both structures are listed on the Denver Historic Register and the National Register of Historic Places, demanding meticulous care to maintain their historic integrity.

The Challenge

The project required:

✅ Assessing historic steel and wood double-hung windows for restoration or replacement.

✅ Developing a cost-effective plan while adhering to preservation guidelines.

✅ Completing the work with minimal disruption to hotel guests and operations.

Previous renovations had added large storm windows, creating a challenge to balance historic authenticity with modern energy efficiency.

Our Solution

In collaboration with the Denver Historic Commission and Complete Property Services, Arnold & Associates, Inc. executed a preservation-focused restoration:

✅ Wood Windows: Restored, resealed, repaired, and fitted with new exterior storm windows for added protection.

✅ Steel Windows: Repaired, sealed, repainted (inside and out), and paired with reinstalled interior storm windows.

✅ Broken Glass Replacement: Preserved historic authenticity while ensuring durability.

This approach preserved the buildings’ heritage while improving energy efficiency and window longevity.

Project Details

✅ Timeline: March 2017 – September 2017

✅ Cost: Approximately $1,513,000

✅ Contractor: Arnold & Associates, Inc.

✅ Project Manager: Denise Pickles Schroderbek (407-982-4160)

Results

✅ Preserved historic charm: Maintained the architectural integrity of two Denver landmarks.

✅ Improved Efficiency: Upgraded windows for enhanced energy performance while maintaining heritage.

✅ Seamless Execution: Finished on schedule and within budget, causing no disruption to hotel operations or guest comfort.

Why It Matters

The restored windows not only enhance the aesthetic appeal of Hotel Monaco Denver but also ensure its legacy as a historic and welcoming destination for travelers. This project showcases how preservation and modern hospitality can coexist beautifully.

Discover the timeless elegance of Hotel Monaco Denver, where history meets modern luxury.

Project Name: Hotel Monaco Denver, Denver, Colorado

Owner: Xenia Hotels & Resorts, Inc.

Project Manager: Denise Pickles Schroderbek 407-982-4160

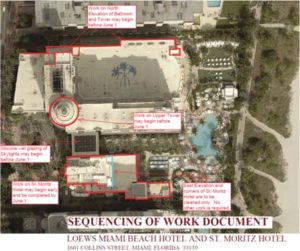

Loews Miami Beach, Florida

Project Overview

The iconic Loews Miami Beach Hotel, encompassing the historic St. Moritz, faced significant exterior challenges due to deteriorating stucco surfaces caused by prolonged exposure to salts and UV light. The client, Loews Hotels & Co., aimed to revitalize the hotel’s exterior with advanced coating materials, sealants, and fresh paint across all exterior walls, including specialty coping metal for decorative elements. The project required meticulous stucco repairs before coating, all while the hotel remained operational during a simultaneous interior lobby remodeling and pool deck project.

Client Objectives

✅ Exterior Upgrade: Restore the hotel’s facade to its original grandeur with durable, high-quality materials.

✅ Tight Timeline: Complete the project by December 2016, aligning with South Beach’s peak tourist season.

✅ Minimal Disruption: Execute all work with the hotel fully operational, ensuring guest satisfaction and uninterrupted hotel functions.

✅ Weather Resilience: Account for potential tropical storms, a common occurrence in Miami, within the project scope.

Our Solution

Arnold & Associates, Inc., led by consultant Michael L. Cogburn, AIA, CSI, delivered comprehensive plans and specifications for competitive bidding and construction. In close collaboration with Loews Hotels’ Director of Engineering, Andre Thuijs, and the hotel management team, we partnered with Capital Contractor Services (CCS) to execute the project. Key highlights include:

✅ Strategic Coordination: Seamless collaboration between the hotel staff, owner, consultant, and contractor ensured minimal disruption to guests despite ongoing interior renovations and a tropical storm event.

✅ Weather Preparedness: The project scope included demobilization and remobilization plans, allowing the team to navigate the storm without delays or additional costs.

✅ Exceptional Execution: The contractor adhered to the tight summer 2016 schedule, delivering high-quality workmanship within the approved budget of approximately $1,101,000.

Results

The facade restoration was a resounding success, restoring the Loews Miami Beach Hotel to its iconic status on Collins Street in South Beach. The project was completed on time, within budget, and with outstanding craftsmanship, enhancing the hotel’s aesthetic appeal and durability while maintaining uninterrupted guest services.

Project Details

✅ Client: Loews Hotels & Co.

✅ Location: Loews Miami Beach Hotel, South Beach, Miami

✅ Project Cost: ~$1,101,000

✅ Contractor: Capital Contractor Services (CCS)

✅ Consultant: Michael L. Cogburn, AIA, CSI, Arnold & Associates, Inc.

✅ Director of Engineering: Andre Thuijs

✅ Completion Date: December 2016

Why Choose Arnold & Associates, Inc.?

This project exemplifies our commitment to delivering high-quality facade restoration solutions with precision, efficiency, and minimal disruption. Our expertise in coordinating complex projects under tight schedules ensures exceptional results for iconic properties like the Loews Miami Beach Hotel.

For expert facade restoration and project management, contact Arnold & Associates, Inc. to elevate your property’s aesthetic and structural integrity.

Montage Hotel y Villas Bahia de Santa Maria Cabo San Lucas, BCS, Mexico

Montage Hotel y Villas Roof Replacement: A Case Study in Effective Roof Failure Solutions

Project Overview

The Montage Hotel y Villas in Cabo San Lucas, Mexico, faced significant challenges during its construction due to roof failures following Tropical Storm Lidia in September 2017. These failures caused work stoppages and damage to interior finishes, threatening the project’s tight completion timeline for the summer of 2018. Arnold & Associates, Inc. (AAI), led by Lyle J. Shive, REWC, RRO, was engaged to evaluate the issues, recommend solutions, and oversee corrective actions to ensure the project met its deadlines.

Client Objectives

✅ Assess Roof Failures: Identify the causes of roof system failures that led to water damage and construction delays after Tropical Storm Lidia.

✅ Coordinate Corrective Actions: Work with the Architect of Record and General Contractor to implement design changes and corrective procedures.

✅ Optimize Solutions: Select roofing solutions based on local material availability, the expertise of local roofing companies, and the project’s tight timeline.

✅ Meet Deadlines: Complete roof replacements while construction continued, ensuring the hotel’s opening by summer 2018.

Project Background

Construction of the Montage Hotel y Villas began in late 2016, with an initial completion date of March 2018. The development includes a main hotel with reception, ballroom, restaurant, retail, and spa facilities, plus 8 residential villas, over 30 guest cabanas, and various outbuildings for services like security, tennis, and dining. Tropical Storm Lidia exposed critical flaws in the roofing systems, prompting an urgent response to prevent further delays and damage.

Identified Issues

The original roof system consisted of:

✅ A structural concrete roof deck with fluid-applied asphaltic waterproofing.

✅ 2-inch EPS foam insulation boards, loose-laid before the waterproofing cured.

✅ A topping of standard and lightweight concrete, coated with spray-applied polyurea.

This hybrid system exhibited widespread cracking, allowing water infiltration into interior spaces. “Dead flat” deck conditions and internal drain bowl assemblies prevented proper drainage, leading to standing water and deterioration of the waterproofing. Approximately 30 buildings were affected at the time of AAI’s review.

Comprehensive Solution

AAI recommended a complete demolition of the failed roof assemblies down to the structural decks, a process that began in November 2017 and continued through April 2018. The proposed solution included:

✅ New Insulation System: Application of polyurethane spray foam insulation over prepared concrete decks.

✅ Roof Membrane: A spray-applied polyurea coating, topped with a compatible paint coating for durability.

✅ Ongoing Oversight: AAI conducted multi-day site visits every two weeks to monitor progress and ensure quality.

✅ Final Review: Post-installation, AAI provided a detailed punch list of deficient items for correction.

This work, spanning December 2017 to July 2018, allowed the hotel to adjust its opening from March to June 2018, maintaining the overall project timeline.

Results

The roof replacement project was successfully completed, enabling the Montage Hotel y Villas to meet its revised summer 2018 opening. AAI’s expertise ensured the new roofing system was robust, compatible with local conditions, and installed by skilled local contractors. AAI continues to support additional projects within the Twin Dolphins development, of which Montage Hotel y Villas is a part.

Project Details

✅ Location: Cabo San Lucas, BCS, Mexico

✅ Owner: Ohana Real Estate Investors

✅ Construction Manager: Thor/Urbana

✅ Project Manager: Mr. Vicente Madrid (+52 55 3223 6308)

✅ Consultant: Arnold & Associates, Inc.

For expert roof failure analysis and corrective solutions, contact Arnold & Associates, Inc. to ensure your project stays on track.

National Rice Mill Lofts

Client’s Objectives:

- Stop leaks through the historic exterior masonry wall system.

- Restore exterior masonry wall construction to a water-resistant assembly with 100% tuckpointing of all mortar and removal/replacement of all broken brick.

- Improve water resistance with the installation of masonry water repellents and new joint sealants.

Solution:

Three (3) story-heavy masonry brick structure originally used as a rice mill in the early 1900s required extensive leak repair, masonry waterproofing, and waterproofing restoration including extensive masonry repair and installation of a penetrating masonry repellent/sealer.

Once the largest rice mill in North America, the building was repurposed for ownership loft living. Designed and developed by Sean Cummings and Anthony “T.J.” Iarocci, in association with architect Wayne Troyer and designer LM Pagano, it contains 69 lofts, townhouses, and studios ranging from one to three bedrooms and 750 to 2100 square feet. The Rice Mill was renovated by Gibbs Construction. Infused with the personality of a boutique hotel as much as the residential one, it opened on September 1, 2011.

The repurposing design and construction did not provide for needed through masonry repairs, wall flashings, and end dams to prevent water from migrating into interior spaces. A number of “bad experiences” prompted the hiring a waterproofing consultant to resolve continual leak issues in the exterior wall assembly. Arnold & Associates, Inc. was selected to proceed with completing analysis, design, and construction documents for weatherproofing the heavy masonry exterior.

After initial evaluations and extensive mockup testing of the exterior masonry wall systems, Arnold & Associates, Inc identified the sources of water infiltration in the exterior walls of the facility.

Arnold & Associates designed correction by insisting on a major exterior masonry repair project including 100% masonry mortar tuckpointing, broken brick removal/replacement, and wall construction repairs including removal/replacement of failed joint sealants. The project was continued and specifications were written, details drawn, and experience waterproofing contractors were contacted to bid the work.

Construction needed to improve the building weather resistance began in 2012 and was completed in 2013 by Frontier Waterproofing, Denton, Texas.

Total Project Cost = Approximately $568,580.00

W New Orleans, 333 Poydras Street, New Orleans, LA | Starwood Hotels & Resorts Worldwide, Inc.

Client’s Objectives:

Client’s Objectives:

- Evaluate the existing curtain wall system to determine the extent of the failure of existing gaskets and frame design.

- Determine the source of leakage at the intersection of the curtainwall system and roof areas where water is leaking into the hotel.

- Determine a Probable Summary of Costs for Correction.

Solution:

The W New Orleans is a recently converted and renovated 24 story hotel property located in downtown New Orleans adjacent to Harrah’s Casino. The exterior curtain wall system is glazed with reflective glass in dark bronze anodized frames with spandrel glass panels at each floor level.

Arnold & Associates, Inc. conducted an extensive review of the hotel facility focusing on those leak issues which have become evident after the major hotel conversion and addition in 1999-2000, approximately (3) years ago.

Arnold and Associates, Inc. Consultant Michael L. Cogburn, AIA, CSI completed the review from a two-man basket on two separate drops on separate sides of the building. Additionally, a full examination of the sill condition of the curtainwall system above the roof areas was completed.

Aged gaskets were brittle causing leakage through the window system. Inappropriate seaman installation which dams up the designed weeping systems of the curtainwall system above fourth-floor roof areas is recommended to be corrected immediately to allow the use of meeting rooms and guest rooms during rain conditions. Additional testing requiring a full removal of the lower sections of the curtainwall system (sill, subsoil, glass, etc.) was suggested and recommended to fully understand the conditions which exist that allow water to enter the inside of the guest room spaces adjacent to this wall condition at the fourth floor

Embassy Suites by Hilton San Juan - Roof Damage

Client’s Objectives

✅ Evaluate hurricane damage to the hotel.

✅ Determine a probable summary of costs for replacement.

✅ Complete the project on time and within budget.

Solution

In 2017, Embassy Suites by Hilton San Juan sustained significant damage from a major hurricane, affecting its three distinct roof systems: a steep slope standing seam, a low slope PVC (polyvinyl chloride) system, and a coating system over concrete decking. The damage included:

✅ Major sections of the metal roof were blown off.

✅ Sections of the low-slope PVC roof detached.

✅ Roof coating system struck by storm-driven debris.

✅ Displaced exhaust fans, dismantled ductwork, and condensers blown off their bases.

Project Scope

The primary goal was to restore the roof to a watertight condition and implement long-term replacements. The highest roofs, featuring standing seam systems, are located approximately 100 feet above ground level and required designs to withstand wind speeds of at least 150 miles per hour.

Key Actions Taken:

✅ Standing Seam Roof (High Slope):

- Reduced panel width to 16 inches using 0.040-inch panels.

- Installed new underlayment.

- Reduced hat channel spacing, fastening to decking at 6-inch centers.

- Decreased clip spacing and used stainless-steel fasteners and clips for enhanced durability.

✅ Low Slope PVC Roof:

- Mechanically fastened a base to lightweight insulation.

- Heat-welded SBS (styrene butadiene styrene) base and cap layers.

✅ Concrete Roof:

- Cleaned and re-roofed with a liquid membrane system.

✅ Additional Repairs:

- Rebuilt ductwork.

- Installed new hurricane-resistant stands for condensers.

- Added crossover structures where required.

- Replaced exhaust fans.

- Upgraded electrical systems to meet current code standards.

- Replaced internal drains to improve drainage capacity.

Project Details

✅ Start Date: March 2017

✅ Completion Date: September 2017

✅ Project Consultant: Gary L. Mitchell, RRC, RRO, CCCA

✅ Project Cost: $1,267,000

✅ Project Owner: Blackstone

The project was completed on time and within budget, ensuring the hotel’s roof systems were restored to withstand future environmental challenges while meeting all regulatory requirements.

|

|

|

Embassy Suites by Hilton, San Juan, PR - Skylight Replacement

Skylight Replacement Project for Hotel Atrium

Project Objectives

✅ Evaluate Existing Skylight: Assess the condition of the large atrium skylight to identify issues and determine suitable replacement options.

✅ Cost Estimation: Provide a probable summary of costs for skylight replacement options.

✅ Minimize Disruption: Complete the project with minimal impact on hotel operations and guest experience.

Project Overview

In 2013, Arnold & Associates, Inc. was engaged by the property owner, Blackstone, to address ongoing issues with a large atrium skylight at a hotel. The skylight, a Kalwall-manufactured aluminum structure, was experiencing persistent leaks despite multiple repair attempts. The goal was to evaluate the skylight’s condition, recommend solutions, and execute the project while the hotel remained fully operational.

Skylight Specifications

✅ Structure: Aluminum structural skylight with 2-3/4-inch thick translucent panels.

✅ Slope: 3 in 12.

✅ Purlin Tubes: Two 4-inch x 4-inch x 1/8-inch aluminum purlins spaced at 7 feet 10- 5/16 inches and 18 feet 8-11/16 inches on each side of the ridge.

✅ Wind Bracing: 4-inch x 4-inch x 1/8-inch aluminum tube.

✅ Loads

- Dead load: 7 psf.

- Live load: 20 psf.

- Wind loading (ASCE 7-93):

- Cladding fastener uplift: 68.2 psf (field), 110.8 psf (perimeter).

- Cladding panels: 49.5 psf (field), 93.9 psf (perimeter).

- Rafters: 36.0 psf (field), 76.6 psf (perimeter).

Issues Identified

A thorough field investigation revealed:

✅ Persistent leaks at panel junctions, leading to moisture infiltration into the building.

✅ Standing water at the junction of two elevator shafts and skylight.

✅ Moisture infiltration at the wall-skylight junction in both elevator shafts.

✅ Fiberglass bloom causing panel surface cracking.

✅ Backing out of fasteners in multiple locations.

Solutions Implemented

Arnold & Associates, Inc. recommended a comprehensive replacement strategy to address the skylight’s issues while ensuring long-term durability and minimal disruption to hotel operations:

✅ Panel Replacement: All translucent panels were replaced to eliminate leaks and address fiberglass bloom.

✅ Additional Bracing: Bracing was added at the elevator shaft junctions to create a positive slope, preventing water ponding.

✅ Flashing Installation: Aluminum angle flashing with silicon tape was installed at wall perimeters to enhance water resistance.

✅ Protective Coating: A coating was applied to the new panels to prevent fiberglass bloom and extend panel lifespan.

✅ Fastener Upgrades: Additional fasteners were installed to improve wind load uplift resistance.

Project Details

✅ Consultant: Gary L. Mitchell, RRC, RRO, CCCA.

✅ Total Cost: $639,666.00.

✅ Owner: Blackstone.

✅ Completion: The project was completed with minimal disruption to hotel operations, ensuring guests experienced no significant inconvenience.

|

|

|

Why Choose Arnold & Associates, Inc.?

Arnold & Associates, Inc. specializes in providing high-quality, cost-effective solutions for complex building envelope issues. Our expertise in skylight replacement and dedication to reducing operational disruptions make us the ideal partner for property owners seeking durable, long-term solutions.

For professional skylight evaluation and replacement services, contact Arnold & Associates, Inc. today.

Hilton Baton Rouge Capital Center: Baton Rouge, LA

Client’s Objectives:

- Evaluate existing hotels in the historic area of Baton Rouge for below-grade waterproofing.

- Evaluate existing historic drainage tunnel near the hotel for hotel usage.

- Determine a Probable Summary of Costs for below-grade waterproofing options.

- Complete the project while the Hotel is operating with minimal disruption to guests and hotel functions.

Solution:

Built-in 1929, Hilton Baton Rouge Capital Center is located downtown Baton Rouge Historic area on the banks of the Mississippi River. The Mississippi River is about 238 feet from the hotel with a berm, and road separating them. The below-grade area is an occupied space with water infiltrating the wall and floor system.

It was difficult determining the water level at the exterior, but it is believed that the water level is above the concrete floor slab. The water level fluctuates throughout the year but is at its highest during the spring when the snow melts from the Northern states and flows into the Mississippi. In the historic area of Baton Rouge, there are underground tunnels, many of which have been infilled. The hotel has one which shows the history of the City. The Ownership wanted to build a restaurant depicting the cities history in this area and use the tunnel as a showplace.

It was difficult determining the water level at the exterior, but it is believed that the water level is above the concrete floor slab. The water level fluctuates throughout the year but is at its highest during the spring when the snow melts from the Northern states and flows into the Mississippi. In the historic area of Baton Rouge, there are underground tunnels, many of which have been infilled. The hotel has one which shows the history of the City. The Ownership wanted to build a restaurant depicting the cities history in this area and use the tunnel as a showplace.

Our first course of action was to stop the infiltration of moisture. Most of the water was infiltrating between the floor slab and concrete wall. After reviewing several manufacturers, Koester a German waterproofing system was selected. This system was designed for this application. A Waterproofing Contractor was selected.

Our first course of action was to stop the infiltration of moisture. Most of the water was infiltrating between the floor slab and concrete wall. After reviewing several manufacturers, Koester a German waterproofing system was selected. This system was designed for this application. A Waterproofing Contractor was selected.

Although somewhat unsure of how the waterproofing system would work against the Mississippi River, I visited the site several years later with no additional infiltration noted, and the Owner had started renovations.

Although somewhat unsure of how the waterproofing system would work against the Mississippi River, I visited the site several years later with no additional infiltration noted, and the Owner had started renovations.

Arnold’s Project Consultant: Gary L. Mitchell, RRC, RRO, CCCA

Project Costs: $77,985.00

Project Owner: Rockbridge Capital

Hilton Baton Rouge Capital Center Baton Rouge, LA: Pool Deck

Waterproofing Solutions for Hilton Baton Rouge Capital Center

Overview

Located in the historic downtown area of Baton Rouge along the Mississippi River, the Hilton Baton Rouge Capital Center, built in 1929, faced significant challenges with water infiltration in its below-grade occupied spaces. Our team was tasked with evaluating the hotel’s below-grade waterproofing, assessing a historic drainage tunnel for potential use, and providing cost-effective solutions with minimal disruption to hotel operations.

Challenges

✅ Water Infiltration: The below-grade area experienced water seepage through the walls and floor slab, primarily at the junction, due to the proximity of the Mississippi River, approximately 238 feet away, separated by a berm and road.

✅ Fluctuating Water Levels: The river’s water level, especially high during spring snowmelt from northern states, complicated waterproofing efforts.

✅ Historic Drainage Tunnel: An existing underground tunnel, reflective of Baton Rouge’s history, was considered for conversion into a restaurant showcasing the city’s heritage.

✅ Operational Continuity: The project needed to be completed without disrupting hotel guests or functions.

Solutions

Our team conducted a thorough evaluation of the below-grade waterproofing needs and the historic drainage tunnel. Key actions included:

✅ Waterproofing System Selection: After reviewing multiple options, we chose the Koester waterproofing system, a German-engineered solution ideal for addressing water infiltration at the floor-wall junction.

✅ Professional Implementation: A specialized waterproofing contractor was hired to install the system, ensuring precision and durability.

✅ Tunnel Assessment: The historic drainage tunnel was evaluated for structural integrity and potential use as a unique restaurant space, aligning with the owner’s vision to highlight Baton Rouge’s history.

Results

✅ Successful Waterproofing: A follow-up visit years later confirmed no further water infiltration, validating the effectiveness of the Koester system against the Mississippi River’s challenges.

✅ Minimal Disruption: The project was completed seamlessly, allowing the hotel to maintain normal operations throughout.

✅ Ongoing Renovations: The owner proceeded with renovations, including plans to transform the historic tunnel into a restaurant, enhancing the hotel’s cultural appeal.

Project Details

✅ Consultant: Gary L. Mitchell, RRC, RRO, CCCA

✅ Project Cost: $77,985.00

✅ Project Owner: Rockbridge Capital

✅ Location: Hilton Baton Rouge Capital Center, Downtown Baton Rouge, Louisiana

|

|

|

Why Choose Our Waterproofing Expertise?

Our team specializes in delivering tailored waterproofing solutions for historic and operational properties. By combining advanced technology, such as the Koester system, with meticulous planning, we ensure long-lasting results with minimal disruption. Contact us to learn how we can protect your property from water damage while preserving its historical value.

Keywords: Below-grade waterproofing, historic building restoration, Hilton Baton Rouge, Mississippi River waterproofing, Koester waterproofing system, drainage tunnel renovation, Baton Rouge historic area.

Sheraton Kauai – Poipu Beach, Koloa, Kauai, HI

Sheraton Kauai Exterior Renovation:

Restoring Poipu Beach’s Iconic Resort

Project Overview

The Sheraton Kauai, located in Poipu Beach, Koloa, Kauai, Hawaii, underwent a comprehensive exterior renovation to address structural deterioration, enhance aesthetics, and ensure guest comfort. Originally built in 1987, the resort was significantly impacted by Hurricane Iniki in 1992, leading to the reconstruction of its Beach Side in 1995. The property comprises three distinct sections—Oceanside, Beach Side, and Garden Side—along with amenities like a lobby, shops, restaurants, bars, pools, ballrooms, and offices.

This project, managed by Arnold and Associates, Inc., focused on evaluating and repairing concrete spalling, stucco cracking, and Exterior Insulation and Finishing Systems (EIFS) issues while resolving balcony leaks and refreshing the hotel’s exterior appearance. Completed between May and September 2008, the renovation was executed with minimal disruption to hotel operations, ensuring guests continued to enjoy their stay.

Objectives

✅ Assess Structural Integrity: Evaluate concrete, stucco, and EIFS systems to determine the extent of concrete spalling and stucco cracking, designing solutions to halt deterioration.

✅ Resolve Balcony Leakage: Identify and address the source of water leaks on guest room balconies.

✅ Modernize Aesthetics: Update and refresh the exterior walls to enhance the resort’s visual appeal.

✅ Cost Estimation: Provide a probable cost summary for the repairs and upgrades.

✅ Minimize Disruption: Complete the project during hotel operations with minimal impact on guests and staff.

Property Details

The Sheraton Kauai consists of:

✅ Oceanside: Two structural concrete buildings, including a four-story tower and a two-story building.

✅ Beach Side: Three four-story structural steel buildings with stucco and EIFS veneers, located around the main pool area.

✅ Garden Side: Located across the road, complementing the resort’s diverse layout.

✅ Additional Facilities: Lobby, shops, restaurants, bars, pools, ballrooms, and office spaces.

Hurricane Iniki, a Category 4 storm, destroyed the Beach Side in 1992, leading to its reconstruction in 1995. The Oceanside and other structures required targeted repairs to maintain structural integrity and guest safety.

Solutions and Implementation

Arnold and Associates, Inc., led by Edward L. Arnold, RRC, RWC, and William G. Hobgood, III, RRO, conducted a thorough assessment of the hotel’s exterior. Key actions included:

✅ Structural Evaluation: Noted concrete spalling in the Oceanside towers and stucco/EIFS cracking in the Beach Side buildings.

✅ Leak Investigation: Identified the sources of balcony leaks to prevent water damage and ensure guest comfort.

✅ Aesthetic Upgrade: Created a new color scheme to modernize the resort’s exterior while keeping its tropical charm.

✅ Project Execution: After identifying repair areas, the project was put out for bid. Work started in May 2008 and finished by September 2008, following a strict timeline to minimize guest disruption.

Project Summary

✅ Project Name: Sheraton Kauai – Poipu Beach, Koloa, Kauai, Hawaii

✅ Owner: Starwood Hotels & Resorts Worldwide, Inc.

✅ General Manager: Angela Vento (Contact: 808.742.1661)

✅ Director of Engineering: Jason Hasenberg

✅ Probable Cost: Approximately $1,279,000

✅ Timeline: May 2008 – September 2008

Why This Matters

The Sheraton Kauai renovation project showcases how targeted structural repairs and aesthetic upgrades can extend the lifespan of a historic resort while enhancing guest experience. By addressing critical issues like concrete deterioration and balcony leaks, the project ensured the property’s longevity and safety. The refreshed exterior design aligns with modern aesthetic standards, making the Sheraton Kauai a standout destination in Poipu Beach.

For more information on similar renovation projects or to explore partnership opportunities, contact Arnold and Associates, Inc.

Lubbock State Supported Living Center, Lubbock, TX

Lubbock State Supported Living Center Roof Replacement Project

Project Overview

The Lubbock State Supported Living Center in Lubbock, Texas, underwent a comprehensive roof replacement project for multiple facilities, covering approximately 200,000 square feet. The Texas Department of Health & Human Services Commission engaged Arnold & Associates, Inc. to investigate and specify the replacement of a 35-year-old roofing and gravel surfacing system across 20 buildings on the campus.

Project Objectives

✅ Replace outdated roofing systems across multiple buildings.

✅ Remove existing gravel surfacing and asphaltic built-up roofing.

✅ Install a modern, durable roofing solution to enhance building functionality and aesthetics.

Solution

Arnold & Associates, Inc. designed and specified a high-performance roofing system to meet the client’s needs. Key project details include:

✅ Scope: Replacement of roofing systems on 20 buildings with gable-configured roofs installed over structural gypsum planks.

✅ Materials: Removal of existing gravel and installation of a gypsum recover board topped with a 60 mil PVC membrane in a ribbed design (Sarnafil Decor System).

✅ Design Enhancements: Incorporation of multiple color schemes to improve building identification across the campus.

✅ Warranty: The new roofing system is backed by a 20-year manufacturer’s warranty.

Expertise and Experience

Arnold & Associates, Inc. has partnered with the Texas Department of Health & Human Services Commission for over 15 years, delivering roofing and waterproofing consulting services. In the past three years, the firm has completed major roofing projects across 12 campuses, including a similar 200,000-square-foot roof replacement initiative in Abilene, Texas.

Project Summary

✅ Project Cost: $2,200,000

✅ Client: Texas Department of Health & Human Services Commission, Austin, TX

✅ Services: Roofing and Waterproofing Consulting

✅ Senior Project Consultant: Syd N. Singer, Arnold & Associates, Inc.

Why Choose Arnold & Associates, Inc.?

With extensive experience in large-scale roofing projects and a proven track record with state agencies, Arnold & Associates, Inc. delivers reliable, high-quality solutions tailored to client needs. Contact us to learn more about our roofing and waterproofing consulting services for state-supported facilities.

Client Objectives:

- Roof replacement for multiple facilities of various square footage totaling approximately 200,000 square feet..

- Investigate and specify the replacement of the existing roofing and gravel surfacing system.

Solution

The Texas Department of Health & Human Services Commission directly hired Arnold & Associates, Inc. to investigate and specify the replacement of the existing roofing and gravel surfacing system which was more than thirty-five (35) years old over twenty (20) buildings at the campus in Lubbock, Texas. The existing roofing, which was sloped in gable configuration, was installed directly to structural gypsum planks.

The Texas Department of Health & Human Services Commission directly hired Arnold & Associates, Inc. to investigate and specify the replacement of the existing roofing and gravel surfacing system which was more than thirty-five (35) years old over twenty (20) buildings at the campus in Lubbock, Texas. The existing roofing, which was sloped in gable configuration, was installed directly to structural gypsum planks.

The gravel was removed from the asphaltic built up roofing on each building in preparation for installing a layer of gypsum recover board and 60 mil PVC membrane in a ribbed design (Sarnafil Decor System). The roof areas were designed with several different colors selected to enhance the identification of each building on the campus. The new roofing system is warranted by the manufacturer for twenty (20) years.

Arnold & Associates, Inc. has been working for the Texas Department of Health & Human Services Commission for approximately fifteen (15) years with work in major phases on twelve (12) campuses in the last three (3) years. Currently, Arnold & Associates, Inc. is working on other campuses including approximately 200,000 square feet of total roof area on multiple buildings in Abilene, Texas.

Summary

- Roof Replacement: $2,200,000.00.

- Owner: Texas Department of Health & Human Services Commission, Austin, TX.

- Services Provided: Roofing and Waterproofing Consulting

- Senior Project Consultant: Syd N. Singer, Arnold & Assoicates, Inc.

Hilton Rose Hall Resort & Spa, Montego Bay, Jamaica

Rose Hall Resort and Country Club: Comprehensive Roofing and Facade Renovation

Project Overview

Rose Hall Resort and Country Club, a premier hospitality destination, faced significant challenges with water leakage and structural deterioration across its roofing, facade, balcony, and fenestration systems. Arnold & Associates, Inc. was engaged to evaluate these issues, identify the sources of failure, and develop a strategic five-year plan for repair and renovation. This case study outlines the evaluation process, solutions implemented, and the successful outcomes achieved, ensuring compliance with ASTM E 2128 standards.

Client Objectives

The primary goals for the project included:

✅ Conducting a thorough evaluation of the existing roof and facade systems per ASTM E 2128 (“Standard Guide for Evaluating Water Leakage of Building Walls”) to assess the extent of failures in roofing, balconies, fenestration, and facade systems.

✅ Identifying the sources of water leakage, documenting conditions with detailed photographs and drawings.

✅ Developing a comprehensive five-year plan for system replacement and renovation, incorporating short-term and long-term goals to ensure durability and performance.

Property Description

Rose Hall Resort and Country Club comprises:

✅ Two main towers connected by a central link housing the main entrance, shops, administrative offices, and dining areas.

✅ Separate buildings for living quarters, a golf pro-shop, and maintenance facilities.

Roofing Systems:

✅ Hotel: Sprayed polyurethane over a built-up roof system on a concrete deck.

✅ Living Quarters: Wood frame with underlayment and asphalt shingles.

✅ Pro Shop and Maintenance: Wood frame with wood shingles.

Challenges Identified

Arnold & Associates conducted an in-depth evaluation, uncovering significant issues:

✅ Fenestration Failures: Over 300 sliding glass doors in guest rooms exhibited failed framing, bearings, and waterproofing, leading to water infiltration.

✅ Concrete Balconies: Significant spalling and rebar rusting, posing safety hazards due to the risk of falling concrete.

✅ Hotel Roof System: Water trapped between the sprayed polyurethane and built-up roof layers created a “waterbed” effect, causing leaks into the hotel interior.

✅ Pro Shop and Maintenance Roofs: Severe deterioration of wood shake shingles resulted in water infiltration.

Solutions Implemented

Immediate Leak Mitigation

The priority was to halt active leaks to stabilize the property while developing long-term solutions. Key actions included:

✅ Emergency Repairs: Specifications for immediate leak repairs were developed and implemented, costing $229,000.

✅ Hurricane Ivan Response: Following a direct hit from Hurricane Ivan, emergency specifications were created for the replacement of over 40 damaged sliding glass doors.

Long-Term Renovation Plan

A five-year plan was established to address all identified issues, with design criteria including:

✅ Upgrading the roofing R-value from 2 to over R-15 for improved energy efficiency.

✅ Ensuring systems could withstand wind loads exceeding 150 mph for enhanced durability.

Key Renovation Projects

- Roof Replacement:

✅ All roofs were replaced with high-performance modified bituminous roof systems and wood shakes where applicable.

✅ Total cost: $2,800,000.

- Sliding Glass Door Replacement:

✅ Over 300 sliding glass doors were replaced with modern, watertight systems.

✅ Total cost: $1,800,000.

-

Concrete Balcony Repairs:

✅ Balconies were rebuilt to address spalling and rebar corrosion, ensuring safety and longevity.

✅ Total cost: $390,000.

-

Storefront Window Replacement:

✅ Storefront windows were replaced to enhance aesthetics and performance.

✅ Total cost: $1,200,000.

-

Facade Recoating:

✅ The facade system was recoated to improve weather resistance and appearance.

Outcomes

The renovation project successfully transformed Rose Hall Resort, addressing all water leakage and structural issues. Key achievements include:

✅ Enhanced Durability: New roofing and fenestration systems meet high wind-load and energy-efficiency standards.

✅ Improved Safety: Rebuilt balconies eliminated the risk of falling concrete.

✅ Restored Aesthetics: The recoated facade and replaced storefront windows enhanced the resort’s visual appeal.

✅ Operational Continuity: Emergency repairs and strategic planning minimized disruptions during the renovation process.

Project Summary

✅ Total Roof Replacement Cost: $2,800,000

✅ Sliding Glass Door Replacement Cost: $1,800,000

✅ Emergency Repairs Cost: $229,000

✅ Concrete Repairs Cost: $390,000

✅. Storefront Replacement Cost: $1,200,000

Why Choose Arnold & Associates?

Arnold & Associates, Inc. has demonstrated expertise in evaluating complex building systems, delivering tailored solutions, and managing large-scale renovations under challenging conditions, including those related to hurricanes. Their adherence to ASTM E 2128 standards ensured a thorough and reliable approach to resolving water leakage and structural issues.

For expert building system evaluations and renovations, contact Arnold & Associates, Inc. to safeguard your property’s performance and longevity.

Keywords: Rose Hall Resort, roofing renovation, facade repair, ASTM E 2128, water leakage, sliding glass door replacement, concrete balcony repair, modified bituminous roofing, hurricane-resistant design, building system evaluation.

Sheraton Halifax Hotel Starwood Hotels & Resorts Worldwide, Inc. Halifax, Nova Scotia, Canada

Sheraton Halifax Hotel Renovation – Halifax, Nova Scotia

Project Overview

The Sheraton Halifax Hotel, managed by Starwood Hotels & Resorts Worldwide, underwent an extensive renovation to address critical structural and aesthetic issues. Located in Halifax, Nova Scotia, this project focused on resolving roof leaks, redesigning the outdoor plaza/sun deck, restoring exterior masonry, and enhancing the visual appeal of the lower roof area visible from tower guest rooms.

Client Objectives

✅ Eliminate Roof Leaks: Address intermittent leaks across 22 deteriorated roof areas.

✅ Redesign Plaza/Sun Deck: Stop leaks and revamp the existing outdoor pool deck.

✅ Restore Masonry Walls: Convert exterior masonry into a water-resistant assembly.

✅ Enhance Aesthetics: Improve the visual appeal of the lower roof area for guest satisfaction.

Solutions Implemented

The project was divided into two major contracts: Roofing and Masonry Restoration, with a total cost of approximately $2.7 million.

Roofing Renovation

✅ Scope: Repaired and replaced 22 existing roofing areas to eliminate leaks.

Pool Deck Redesign: The outdoor pool deck, plagued by multiple leaks, was completely rebuilt. The process included:

✅ Removal of existing landscaping, wood decking, and roofing.

✅ Installation of a 60 mil Sarnafil reinforced single-ply membrane with high-density architectural pavers.

✅ Custom color and pattern selection approved by the owner.

✅ Cost: Approximately $1,250,000.

Masonry Restoration

✅ Scope: Comprehensive restoration of exterior masonry walls to ensure water resistance and structural integrity.

✅ Work Performed:

- Removed and replaced existing sealants and copper through-wall flashings.

- Installed additional vertical control joints and stainless steel end dam protection at all windows.

- Rebuilt the exterior split-face block veneer on a significant portion of the building’s exterior elevation.

- Replaced guardrails/handrails and performed a complete exterior wall cleaning.

✅ Cost: Approximately $1,450,000.

Project Details

✅ Project Name: Sheraton Halifax Hotel Renovation

✅ Location: Halifax, Nova Scotia, Canada

✅ Owner: Starwood Hotels & Resorts Worldwide

✅ Key Contacts:

- P. of Hotel Operations: Jim Hill (902-421-1700)

- Engineer: John Chapman/Gary Crotty (902-421-1700)

- Controller: Mary Banks (902-421-1700)

- Fax: 902-422-5805

✅ Total Project Cost: Approximately $2.7 million

Outcome

The renovation successfully addressed all client objectives, delivering a leak-free roof, a redesigned and functional outdoor pool deck, restored water-resistant masonry walls, and an enhanced aesthetic for guest-facing areas. The project improved both the structural integrity and visual appeal of the Sheraton Halifax Hotel, ensuring long-term durability and guest satisfaction.

Sheraton Suites Plantation Starwood Hotels & Resorts Worldwide, Inc. – Thayer, Inc. Plantation, Florida

Sheraton Suites Plantation: Expert Waterproofing and Roofing Solutions

Arnold & Associates | Thayer, Inc. | Plantation, Florida | Starwood Hotels & Resorts Worldwide, Inc.

Project Overview

Thayer, Inc. collaborated with Sheraton Suites Plantation to deliver comprehensive waterproofing and roofing solutions. This case study highlights how our expertise resolved critical issues, enhanced property aesthetics, and ensured durability against extreme weather conditions.

Client Objectives

✅ Eliminate leaks in the rooftop pool deck for enhanced guest safety and comfort

✅ Prevent leaks in roof areas and upgrade roofing systems with extended warranties

✅ Restore precast concrete panel walls to a fully water-resistant state

✅ Enhance the visual appeal of the lower roof area visible from tower guest rooms

|

|

|

|

Comprehensive Solutions

Thayer, Inc. executed three specialized contracts to meet the client’s goals: Pool Deck Waterproofing, Roofing Upgrades, and Exterior Wall Restoration.

Project 1: Rooftop Pool Deck Waterproofing

The ninth-floor rooftop pool deck was completely replaced to eliminate leaks, ensuring a safe and functional space for guests. This project extended the deck’s lifespan while maintaining cost efficiency.

Project Cost: $126,625.00

Project 2: Roofing Repairs and Upgrades

Roof system repairs and reconditioning were performed to stop leaks and extend the roof’s lifespan by approximately 10 years. The upgraded roofing systems included enhanced warranties, delivering long-term value at a minimal cost.

Project Cost: $83,209.00

Total Cost for Pool Deck and Roofing: $209,834.00

Project 3: Exterior Wall Restoration

Completed in Spring 1999, this project involved the complete removal and replacement of exterior wall sealants in the precast concrete panel system. A robust 18–20 mil thick coating system was applied to all exterior walls, ensuring water resistance. The project’s durability was proven when it withstood two high-magnitude hurricanes (80–100 mph winds) without any leakage.

Project Cost: $212,366.00

Project Outcomes

Thayer, Inc.’s solutions successfully met all client objectives, delivering a leak-free, visually appealing, and durable property. The projects were completed on time, within budget, and demonstrated exceptional resilience against extreme weather, ensuring long-term performance for Sheraton Suites Plantation.

Contact Thayer, Inc. for Your Waterproofing Needs

Thayer, Inc. specializes in commercial waterproofing, roofing, and restoration solutions. Contact us today to learn how we can protect and enhance your property.

Cooper Tire & Rubber Company Albany Manufacturing Facility | Albany, Georgia

Industrial Roof Replacement: Durable and Low-Maintenance Solution

L.E. Schwartz & Son, Inc. | 1.78M Square Foot Facility

Project Overview

L.E. Schwartz & Son, Inc. delivered a comprehensive roof replacement for a massive 1,784,966-square-foot industrial facility. The project was designed to provide a durable, low-maintenance, and elastomeric roofing system capable of withstanding severe operational demands, completed ahead of schedule and under budget.

Client Objectives

✅ Develop a roof assembly resilient to severe operational abuse

✅ Ensure roof damage is easily identifiable and repairable by in-house personnel

✅ Create a roof assembly requiring minimal maintenance throughout its lifespan

✅ Incorporate elastomeric properties for enhanced flexibility and durability

Comprehensive Roofing Solution

The project was executed in six phases over a 14-month period, covering 1,286,496 square feet of roof replacement. L.E. Schwartz & Son, Inc. implemented a robust solution tailored to the client’s needs, completed at a final cost of $6,250,000 against a $7,000,000 budget.

Scope of Work

The roofing solution included:

✅ Removal of existing materials down to the 24-gauge deck

✅ Stiffening the deck assembly with side lap fastening at 18 inches on center

✅ Replacement of deteriorated 24-gauge deck with 18-gauge deck

✅ Cleaning and priming all deck surfaces

✅ Installation of two layers of insulation with staggered joints

✅ Application of a granulated SBS asphalt-modified Built-Up Roofing (B.U.R.) assembly

✅ Installation of aluminum foil-faced SBS flashings

Demolition and Additional Work

Demolition involved the removal of five roof-mounted concrete transformer pads and runways, coordinated with an abatement firm to ensure safety and compliance. Additional specifications included:

✅ Installation of 22-gauge galvanized sheet metal for all expansion joints

✅ Replacement of all internal drains to enhance drainage efficiency

Project Execution and Results

The project was phased into six parts to accommodate the facility’s size and operational needs. Initially planned for 18 months, the project was substantially completed in just 14 months, resulting in both time and cost savings.

Final Project Cost: $6,250,000 (Budget: $7,000,000)

Project Outcomes

L.E. Schwartz & Son, Inc. delivered a high-performance roofing system that met all of the client’s objectives. The new roof assembly is durable, easily maintainable, and elastomeric, ensuring long-term reliability with minimal upkeep. The project’s success is underscored by its completion ahead of schedule and under budget, providing exceptional value for the client.

Contact Arnold and Associates for Roofing Solutions

Arnold & Associates consultants specialize in building envelope, industrial, and commercial roofing and waterproofing solutions. Please reach out to us to learn how we can help you get optimal, durable, cost-effective roofing and waterproofing solutions for your facility.

The Don Cesar Beach Resort and Spa – a Loews Hotel St. Pete Beach, Florida

Restoration of The Don Cesar Beach Resort:

Preserving a Historic Landmark in St. Pete Beach, Florida

The Don Cesar Beach Resort and Spa, a iconic Loews Hotel in St. Pete Beach, Florida, stands as a testament to early 20th-century architecture. Built in 1927, this pink stucco landmark has weathered decades of history, from serving as a WWII hospital to narrowly escaping demolition. In a comprehensive restoration project, the focus was on safeguarding its unique exterior while ensuring minimal disruption to ongoing hotel operations. This case study explores the objectives, solutions, and successful outcomes of the restoration, highlighting expert preservation techniques for historic hotels in Florida.

A Rich History of The Don Cesar Beach Resort

The Don Cesar, often called the “Pink Palace,” has a storied past on Florida’s west coast. Originally constructed in 1927, the hotel’s Mediterranean Revival style features vibrant pink stucco walls that have become synonymous with St. Pete Beach luxury. Over the years, it transitioned from a glamorous resort to a military hospital and convalescence center during World War II, later becoming a VA office building. By the 1970s, it faced demolition threats before being revitalized as a premier beachfront destination under Loews Hotels.

This historic significance made preservation a priority, especially amid signs of structural deterioration. The project aimed to honor its legacy while addressing modern challenges like concrete spalling, stucco cracking, and water leakage—common issues in Florida’s humid coastal environment.

Client Objectives for the Restoration Project

Loews Hotels, Inc., in partnership with Prudential, outlined clear goals to restore the Don Cesar without compromising its operational status or aesthetic integrity:

✅ **Preserve the Iconic Exterior**: Protect the 1927 landmark’s pink stucco walls, sealants, painted finishes, and windows from further deterioration, ensuring the building’s historic charm remains intact.

✅ **Evaluate and Repair Structural Elements**: Assess spalling concrete in decorative cornices, railings, and balustrades. Stabilize wall substrates, quantify the extent of concrete spalling and stucco cracking, and design targeted repairs to halt ongoing damage.

✅ **Address Water Leakage and Color Retention**: Identify sources of exterior wall leaks and implement solutions to prevent future infiltration. Maintain the color fastness of the pink exterior throughout the building for long-term vibrancy.

✅ **Cost Estimation and Efficiency**: Develop a probable summary of costs for all corrective measures, aiming for budget-conscious execution.

✅ **Minimize Operational Disruption**: Complete the work while the hotel remained fully operational, with little to no impact on guests or daily functions—a key consideration for busy Florida beach resorts.

These objectives ensured the project aligned with best practices in historic hotel restoration, balancing preservation with practicality.

The Restoration Solution: Expert Assessment and Execution

In 2004, Arnold and Associates, Inc., with Architect and Senior Consultant Michael L. Cogburn, AIA, CSI, leading the effort, conducted a thorough facility review. The analysis zeroed in on structural deterioration, stucco cracking, and overall building integrity. An initial budget of approximately $1.5 million was set based on these findings.

Once the scope of work was finalized, the project went out for bidding. It was awarded to Valcourt Building Services, a specialist in exterior building restoration. Work commenced in October 2005 and wrapped up by Christmas 2006, demonstrating efficient project management in a live hotel environment.

Key aspects of the solution included:

✅ Advanced diagnostic techniques to pinpoint leakage sources and deterioration causes.

✅ Custom repair designs for concrete and stucco elements, using materials compatible with the original 1927 construction.

✅ Phased implementation to avoid guest disruptions, such as scheduling noisy work during off-peak hours.

The Result?

A revitalized structure that not only stopped deterioration but also enhanced the hotel’s durability against Florida’s coastal elements.

Project Outcomes and Cost Savings

The restoration was a resounding success, coming in substantially under budget at a final cost of approximately $1,040,000—saving over $460,000 from the original estimate. This efficiency underscores the value of expert planning in historic preservation projects.

✅ **Project Name**: The Don Cesar Beach Resort and Spa, St. Pete Beach, Florida

✅ **Owner**: Loews Hotels, Inc. and Prudential

✅ **General Manager**: John Marks (Contact: 727-360-1881)

✅ **Director of Engineering**: John Jones (Contact: 727-360-1881)

✅ **Consultant**: Michael L. Cogburn, AIA, CSI

This project serves as a model for historic hotel renovations in Florida, proving that landmark preservation can be achieved affordably and with minimal downtime.

Why Choose Professional Restoration for Historic Florida Hotels?

Restoring landmarks like The Don Cesar requires specialized knowledge in stucco repair, concrete stabilization, and leak prevention—especially in high-humidity areas like St. Pete Beach. If you’re managing a historic property, partnering with experienced consultants can prevent costly future issues while preserving architectural heritage. For more insights on Florida hotel preservation or similar case studies, explore our resources on historic building restoration techniques.

*Keywords: Don Cesar Beach Resort restoration, historic hotel preservation Florida, St. Pete Beach landmark, stucco repair techniques, concrete spalling solutions*

Presbyterian Hospital Hunt Hospital District Greenville, Texas

Presbyterian Hospital of Greenville Restoration:

Client Objectives for the Restoration Project

The hospital administration outlined clear goals to address chronic water infiltration and restore the building’s exterior integrity:

✅ **Eliminate Water Leaks**: Stop leaks penetrating through windows and the exterior masonry wall system to protect interior spaces, including patient rooms, offices, and conference areas.

✅ **Restore Masonry Wall Integrity**: Convert the exterior masonry wall construction into a fully water-resistant assembly to prevent future water damage.

✅ **Enhance Aesthetic Appeal**: Improve the building’s appearance through comprehensive masonry cleaning and the application of protective coatings, ensuring a polished and professional look for the hospital.

These objectives were critical to maintaining a safe, functional, and visually appealing environment for patients, staff, and visitors.

Challenges: A History of Unresolved Leaks

The Presbyterian Hospital had struggled with water infiltration for years, with one notable executive conference room enduring leaks for eight years without resolution. Previous attempts to fix the issue had led to distrust in consultants and architectural firms, prompting the administration to take a cautious approach. After thorough research into Arnold & Associates, Inc.’s references and multiple discussions, the hospital selected them for their proven expertise in waterproofing and exterior restoration.

The Restoration Solution: Precision Diagnostics and Execution

Arnold & Associates, Inc. began with a comprehensive evaluation and testing phase to identify the root causes of water infiltration. Their findings revealed multiple issues:

✅ **Aging Curtainwall System**: The aluminum curtainwall’s gasket system had deteriorated significantly, allowing windblown rain to penetrate interior spaces during thunderstorms.

✅ **Failing Perimeter Sealants**: Brittle and cracked sealants around the curtainwall and end conditions contributed to substantial water ingress.

✅ **Design Flaws**: The original construction lacked critical through-wall flashings and end dams, enabling water to migrate into offices, patient rooms, and ancillary spaces.

Based on these insights, Arnold & Associates designed a tailored solution:

✅ Installation of new sealants and end dams to fortify the curtainwall system.

✅ Application of penetrating masonry sealer to enhance the brick veneer’s water resistance.

✅ Restoration of cast stone elements to address structural and aesthetic damage.

✅ Comprehensive cleaning of the masonry exterior to restore its visual appeal.

After developing detailed specifications and drawings, the project was put out to bid, and experienced waterproofing contractors were selected. The restoration began and was completed on time and within budget, achieving a leak-free facility.

Project Outcomes: A Leak-Free Hospital

The restoration was a complete success, resolving all water infiltration issues and delivering a revitalized exterior. Key outcomes included:

✅ **No More Leaks**: The hospital, including the problematic executive conference room, became fully water-resistant, protecting interior spaces from future damage

✅ **Enhanced Aesthetics**: Extensive cleaning and coatings restored the masonry’s appearance, improving the hospital’s professional image.

✅ **Cost Efficiency**: The project was completed at a total cost of $202,000, demonstrating effective budget management.

**Project Details**:

✅ **Project Name**: Presbyterian Hospital of Greenville, Greenville, Texas, USA

✅ **Owner**: Presbyterian Hospital of Greenville – Hunt Hospital District

✅ **Director of Support Services**: Karan Ellis (Contact: 903-408-5000, Fax: 903-408-1699)

✅ **Director of Plant Services**: Danny Reed (Contact: 903-408-5000, Fax: 903-408-1009)

Why Choose Expert Waterproofing for Healthcare Facilities?

Hospitals like Presbyterian Hospital of Greenville require specialized solutions to address water infiltration, particularly in Texas’s variable climate. Effective waterproofing not only protects patient care environments but also extends the lifespan of critical infrastructure. By partnering with experienced consultants like Arnold & Associates, facility managers can achieve lasting results without the pitfalls of trial-and-error approaches.

For more information on hospital exterior restoration or waterproofing solutions in Texas, explore our resources on masonry repair and curtainwall system maintenance.

*Keywords: Presbyterian Hospital Greenville restoration, hospital waterproofing Texas, masonry repair solutions, curtainwall leak repair, exterior restoration healthcare facilities*

Sky View Parc, Flushing, NY

Sky View Parc: Roofing and Waterproofing Excellence in Flushing, NY

Project Overview

Sky View Parc, formerly Flushing Town Centre, is a premier multi-use development spanning approximately 14 acres in Flushing, New York, strategically located under the flight path of LaGuardia Airport. This expansive project features large retail spaces at the podium level, a landscaped activity area, an amenity deck atop a multilevel parking structure, and three multi-level residential towers with approximately 448 condominium and apartment units. Future phases are planned to include an additional 619 units, further enhancing the development’s footprint.

Client Objectives

The primary goals for Sky View Parc included:

✅ Roofing and Waterproofing System Selection: Identifying durable, high-performance systems tailored to the project’s unique needs.

✅ Design Specifications and Detailing: Developing comprehensive specifications to ensure seamless integration with the architectural vision.

✅ On-Site Field Observation: Ensuring quality control through meticulous oversight during installation.

Tailored Solutions by Arnold & Associates, Inc.

Arnold & Associates, Inc., in collaboration with Perkins Eastman Architects, landscape architects, mechanical/electrical/plumbing engineers, and owner/developer representatives, delivered a comprehensive solution for Sky View Parc’s roofing and waterproofing needs.

System Selection and Research

After extensive research and analysis, Arnold & Associates, Inc. presented a detailed recommendation for roofing and waterproofing systems. The selection process prioritized durability, compatibility with the project’s design, and compliance with environmental and structural constraints, particularly given the site’s proximity to LaGuardia Airport.

Below-Grade Waterproofing

To prevent water migration and contamination in the lower levels of the development, Arnold & Associates, Inc. specified advanced below-grade waterproofing systems. Key considerations included:

✅ Hydrostatic Pressure Analysis: Materials and thicknesses were carefully determined to withstand below-grade pressures.

✅ Positive-Side Installation: Waterproofing systems were applied to the positive side of structural concrete, including lower slabs, piling caps, and vertical walls.

✅ Quality Assurance: Senior Consultants from Arnold & Associates, Inc., alongside manufacturer’s technical representatives, monitored contractor installation to ensure long-term performance and reliability.

Roofing and Podium-Level Solutions

The podium level, envisioned as a highly landscaped, pedestrian-friendly space, presented unique challenges due to restrictions on roof penetrations and drains. Arnold & Associates, Inc. addressed these challenges by:

✅ Selecting Waterproofing Over Roofing Systems: Waterproofing systems were chosen to accommodate extensive landscaping, hardscaping, and pedestrian walkways, enhancing the aesthetic and functional appeal of the podium level.

✅ Reflective Roofing for Towers: For the three residential towers, reflective roofing systems were specified to integrate seamlessly with mechanical systems and minimize penetrations, ensuring energy efficiency and durability.

✅ Deck Coatings and Flashings: Specialized deck coating systems and sheet metal flashings were incorporated to enhance longevity and performance.

Collaborative Design Integration

Working closely with Perkins Eastman Architects, Arnold & Associates, Inc. ensured that all roofing and waterproofing systems aligned with the project’s architectural and functional goals. The collaborative effort resulted in a cohesive design that balanced aesthetics, performance, and sustainability.

Project Outcome

Phase I of Sky View Parc has been successfully completed, with major portions of the development occupied and retail spaces fully leased. The project has garnered positive feedback for its innovative design and high-quality execution, setting a benchmark for multi-use developments in urban environments.

Key Consultants

✅ Michael L. Cogburn, CSI

✅ William “Bill” Hobgood, III, RRO

Why Choose Arnold & Associates, Inc.?

Arnold & Associates, Inc. brings unparalleled expertise in roofing and waterproofing solutions, delivering tailored, high-performance systems for complex projects like Sky View Parc. Our commitment to research, collaboration, and quality assurance ensures lasting results that meet the highest industry standards.

For more information about our services or to discuss your project needs, contact Arnold & Associates, Inc. today.

St. Regis Aspen Starwood Hotels & Resorts Worldwide, Inc. Aspen, Colorado

St. Regis Aspen Roofing and Plaza Deck Restoration

Project Overview

Client Objectives

✅ Replace Deteriorated Roofing: Swap out worn synthetic slate roofing with high-quality natural slate to match the existing color scheme.

✅ Stop Leaks in Plaza Decks: Repair leaks in the Main Plaza Deck, Courtyard, and Mill Street Plaza Deck while improving drainage systems.

✅ Upgrade Mill Street Plaza Deck: Remove the raised planter area, install a hydronic snowmelt system, and redesign with natural flagstone slabs.

✅ Minimize Disruption: Complete all work before the ski season with minimal noise and operational interference.

Solutions Implemented

Arnold & Associates, Inc. executed two major contracts: one for roofing and another for plaza deck repair and restoration. The projects were completed under tight timelines, ensuring quality and compliance with the hotel’s operational needs.

Project 1: Roofing Replacement

✅ Scope: Replaced 435 squares of synthetic steep-sloped roofing with Vermont natural slate across three hotel buildings.

✅ Additional Work: Included copper sheet metal fabrication and installation of a state-of-the-art ice melt system.

✅ Process:

-

- Developed contract documents under extreme time constraints.

- Coordinated owner-purchased Vermont slate.

- Conducted contractor qualification interviews and managed competitive bidding.

- Provided on-site quality observation to ensure flawless execution.

✅ Timeline: Completed before the winter ski season to avoid operational disruptions.

✅ Total Cost: $1.55 million

Project 2: Plaza Deck Waterproofing and Restoration

✅ Scope: Repaired waterproofing on two plaza deck areas (Main Plaza Deck and Mill Street Plaza Deck) to stop leaks into ballrooms, meeting rooms, and public spaces below.

✅ Key Tasks:

-

-

- Removed and reinstalled Colorado flagstone slabs.

- Installed copper perimeter flashings and waterproofing membranes.

- Removed a large raised planter on the Mill Street Plaza Deck, added waterproofing, and installed a hydronic snowmelt system

-

✅ Timeline: Completed within a four-week construction schedule.

✅ Total Cost: $285,000

Project Outcome

Both projects were delivered on time, within budget, and with minimal disruption to hotel operations. The use of high-quality materials, such as natural Vermont slate and Colorado flagstone, enhanced the property’s aesthetic appeal and long-term durability. The hydronic snowmelt system and improved drainage ensured functionality during Aspen’s harsh winters.

Client Information

✅ Owner: Starwood Hotels & Resorts Worldwide, Inc.

✅ Contact: Mr. David Bray, Corporate Director

✅ Phone: 602-852-3902

✅ Fax: 602-852-0519

Why This Matters

The successful completion of these projects underscores Arnold & Associates’ expertise in managing complex, time-sensitive construction projects for luxury properties. The St. Regis Aspen now boasts a durable, visually stunning exterior that aligns with its five-star reputation, ensuring guest satisfaction and operational excellence.

For more information on similar projects or to inquire about our services, contact Arnold & Associates, Inc.

St. Luke’s Episcopal Hospital, Houston, TX – Tower Waterproofing Project

St. Luke’s Episcopal Hospital Tower Waterproofing Project in Houston, TX

|

|

|

Project Overview

St. Luke’s Episcopal Hospital in Houston, TX, underwent a comprehensive tower waterproofing and restoration project to enhance durability and aesthetics. Butch’s Waterproofing Company of Houston, Texas, delivered innovative solutions, completing the project under budget in just eight months.

Client Objectives

✅ Replace window and control joint sealants to ensure waterproofing.

✅ Conduct masonry repair and tuckpointing for structural integrity.

✅ Clean existing masonry to improve appearance.

✅ Remove heavy oxidation and staining from anodized aluminum window frames.

✅ Eliminate persistent streaking on window glass using specialized cleaning techniques.

Innovative Restoration Solutions

Following a detailed building assessment, Butch’s Waterproofing Company implemented tailored solutions to address challenges while minimizing disruption to hospital operations:

✅ Sealant Replacement: To avoid dust contamination from grinding masonry, new silicone sealant joints were installed over existing sealants using extruded silicone for durable, waterproof joints.

✅ Masonry Restoration: The project included tuckpointing, selective masonry replacement, thorough cleaning, and application of a clear water-repellent to protect against future damage.

✅ Specialized Cleaning:

-

-

- Aluminum Frames: Volcanic pumice was used as an abrasive cleaning agent to remove oxidation and lime deposits from anodized aluminum window frames and louvers.

- Window Glass: Cerium oxide polishing restored clarity to both exterior and interior glass panes, removing persistent streaking.✅ Additional Enhancements: Silicone sealant wet-glazing addressed deteriorating neoprene gaskets, ensuring long-term performance of window systems.

-

Project Outcomes

Originally budgeted at $416,283, the project was completed for $373,400, delivering significant cost savings. The eight-month timeline ensured minimal disruption to hospital operations while achieving high-quality results.

Why Butch’s Waterproofing Company?

Butch’s Waterproofing Company specializes in commercial waterproofing, masonry restoration, and advanced cleaning solutions. Our expertise ensures cost-effective, durable results for properties in Houston and beyond. Contact us to protect and enhance your building today.

Keywords: Houston waterproofing, commercial masonry restoration, window frame cleaning, silicone sealant solutions, tuckpointing services, building maintenance.

Client’s Objectives:

- Provide replacement of existing sealants at the perimeter of windows and control joints

- Provide masonry repair and tuckpointing procedures

- Provide cleaning of existing masonry

- Provide specialized cleaning of anodized aluminum window frames to remove heavy oxidation and staining

- Provide specialized cleaning of window glass to remove streaking which would not clean with typical window cleaning techniques

Solution:

Upon examination of the building, it was noted that to remove existing sealants properly would require excessive grinding of the masonry. The potential of dust entering the hospital rooms due to the grinding was too great. We, therefore, designed the new sealant joints at the perimeter of windows to be installed using extruded silicone spanning over the existing sealant which was allowed to remain in place.

Both the glass and the metal window frames were discolored and stained from lime deposits bleeding out of the precast spandrel panels and from oxidation. The lime deposits were streaked onto the glass and would no longer clean. We recommended the use of a specialized cleaning process for the metal frames utilizing volcanic pumice as an abrasive cleaning agent.